Our clients came to us the summer of 2022 with grand plans to reface their existing fireplace. They wanted a show-stopping feature in their beautiful historical loft, but they were unable to execute the project on their own.

They purchased a unique Stabilized Aluminum Foam panel – imagine a 4×8 sheet product that looks like thousands of can tabs melted and molded together (that’s kind of what it looks like). This product caught our clients’ attention and they hoped they could simply affix the panel to the fireplace. Easier said than done.

Here were some of the questions we had:

- How do we finish the raw edges of the panel?

- How do the sides of the fireplace connect to the front panel?

- How do we light the fireplace to accent the space and show off the materiality?

- Do we add a mantle for décor opportunities?

- Do we replace the hearth? And if so, what finish should it be?

- Who are the right people to implement the work?

This “simple”, small project was all about designing the details and finding a team of crafts-people who would help us execute it to perfection!

CONCEPT PHASE: Information Gathering

First, we did a Discovery Consultation and measured the site. We discovered all the quirks of a historical loft. So many angles, uneven surfaces, and challenging obstacles! This “simple” project became more and more complex as we began investigating.

Then we “hit the drawing board” to develop a few concepts with different treatments, materials, and lighting solutions. This was the fun exploration phase – playing with our 3D rendering program and collaborating with our creative clients to find the perfect solution for their space and their budget.

DESIGN PHASE: Collaboration

Once we determined the preferred design, we brought our team of expert trades to the site (for Trade Day! See our July blog for details about “Trade Day”). Here we collaborated on the details of the project, we discussed how each trade would connect and install their piece of the project, and we determined the order of events.

Each expert brought up their concerns and suggested solutions to solve this puzzle of a project.

Then we went back to the drawings to implement all the details! We also played with a few different lighting mock-ups to ensure the design would function as it was intended, and we made tweaks as necessary.

IMPLEMENTATION PHASE: Expect to Uncover the Unexpected & Things WILL Go Wrong

Then Tracy (our Project Manager) created a construction schedule (our guideline for when each trade needed to complete their work). We set clear expectations and we all agreed on a timeline. We were ready to go and everyone was excited to see this beautiful fireplace come to life.

Ahh… the best laid plans!

One of the big feature items on this project was a set of custom bent and powder coated steel side panels. They would hold the aluminum panel in place, cover the rough edges, and conceal the lighting details. They also featured custom formed metal bolts that reflect original detailing in the condo’s structure. (No detail was left unexplored on this project!) However, with the quirks of a historical (extremely un-level) loft, we did not discover ALL the site discrepancies until the first set up panels were installed. Even though the installation looked good, it wasn’t perfect enough for our meticulous engineer who oversaw the fabrication of the metal. The panels were sent back to the shop and the team remeasured.

During round two of the panels, the paint bubbled; during round three, there was a dent! These panels were cursed and we didn’t know whether to laugh or to cry. Thank goodness for patient clients and persistent crafts-people.

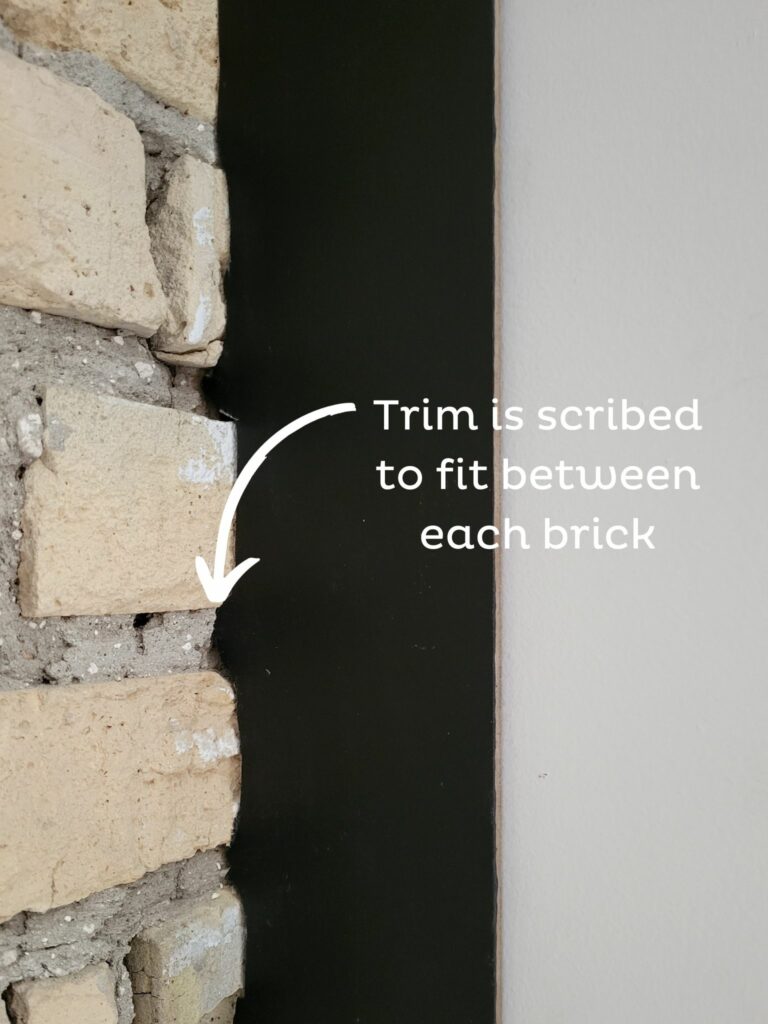

We re-adjusted our timelines and requirements. Our millworker (also meticulous) created a perfectly scribed and stained trim piece that fit within the groves of the brick so that no existing drywall would be evident once the metal panels went in. And let’s not overlook the amazing wood mantle he crafted, stained in the perfect black “India Ink”.

Our tile installer (completing the trifecta of meticulous trades) was patient when we made a last-minute change to the hearth tile (it became apparent once the fireplace finishes were installed that a black hearth would be more fitting than a charcoal one.) He also suggested a large format tile to minimize distracting grout lines.

Everyone was fully invested in the very BEST (not the fastest) solution.

The COMPLETED PRODUCT

The project is finally 100% complete (almost a year after we started) and our clients are thrilled with the result!

We learned many things on this seemingly “small” but intense project. The biggest take-home lesson learned is that small doesn’t mean easy or fast. Often there are just as many details in a small project as there is in a large project.

We also learned the value of working with the right team. We are sincerely grateful to everyone who invested their time, energy, and skills to ensure their part of the project would be perfect and the clients would be happy.

Finally, we are thankful for wonderful clients who remained patient and understanding as timelines extended and work had to be re-done. They kept their eye on the prize and understood the value of doing it right. We’re so glad they now have the show-stopping, jaw-dropping feature fireplace of their dreams!